4013HWBC Flip-Flop Guide: How to Configure, Wire, and Use It Effectively

If you’ve ever tried setting up an automation system or connecting hardware for data management, you know how frustrating it can be when devices don’t communicate or fail to perform as expected. Choosing the right module can save you time, prevent errors, and make your system run smoothly. That’s where the 4013HWBC comes in.

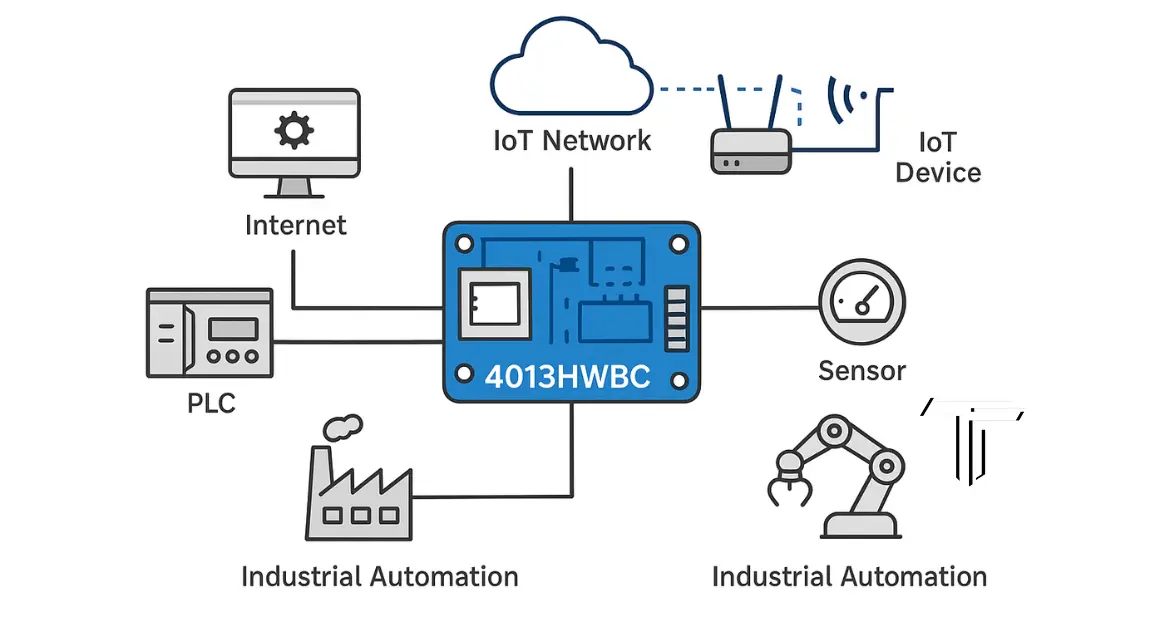

This flip-flop module is designed to handle complex tasks in industrial automation, IoT systems, and data processing setups. It combines high-speed switching, dual relay and input features, and flexible connectivity options. In short, it’s built to simplify tasks that often feel complicated and technical.

In this guide, you’ll learn exactly what the 4013HWBC is, how it works, and why it has become a core component in digital systems. We’ll explore its evolution, key features, technical specifications, real-world applications, and even compare it to similar modules. By the end, you’ll understand not just the hardware itself, but also how it can make your automation projects more reliable and efficient.

Whether you’re setting up a small IoT system or integrating advanced AI workflows, this guide will give you a clear roadmap to using the 4013HWBC effectively.

Table of Contents

What Is the 4013HWBC and How It Works

The 4013HWBC is a dual D-type flip-flop module. Flip-flops are digital logic circuits that store and control binary data. In simple terms, this module can hold a value of either 0 or 1 and switch between these states based on the input it receives.

What makes the 4013HWBC unique is its combination of hardware performance and connectivity. It features:

- Dual relay and input ports for simultaneous control and monitoring

- Ethernet and PoE (Power over Ethernet) connectivity for easy network integration

- Web-enabled control, allowing remote access and monitoring

- Wireless support for IoT applications

These features allow the module to manage multiple tasks at the same time. For example, in a factory automation setup, the 4013HWBC can control machinery while simultaneously collecting and sending data to a server. It can also integrate with AI-based systems to make real-time adjustments to processes.

Compared to standard flip-flops like CD4013BC or HCF4013BE, the 4013HWBC offers more flexibility, better connectivity, and industrial-grade durability. This makes it suitable for applications where performance and reliability are critical.

The Evolution of the 4013HWBC in Digital Systems

Early Development

The concept of flip-flops dates back to the 1960s. Early versions were used in basic computing and timing circuits. Over time, the modules evolved, offering more reliable performance and additional features. Manufacturers like Texas Instruments, STMicroelectronics, and Fairchild Semiconductor played a key role in developing these components.

Modern Integration

Today, the 4013HWBC is not just a flip-flop. It is a web-enabled, industrial-grade module used in automation, IoT, and data management. It integrates with:

- Industrial automation hardware for controlling machinery

- IoT ecosystems for smart devices

- Blockchain networks for secure data handling

This modern version can handle more complex tasks than its predecessors and is easier to integrate into existing systems.

Future Advancements

Looking forward, the 4013HWBC is expected to support advanced AI applications, predictive maintenance systems, and higher-speed industrial networks. These improvements will make it even more valuable for smart factories and automated data centers.

Key Features and Technical Specifications

Here are the main features and specs that make the 4013HWBC a preferred choice for industrial and tech professionals:

Performance & Processing

- High-speed switching with minimal delay

- Reliable storage and transfer of binary data

Connectivity Options

- Ethernet and PoE support

- Wi-Fi and cellular support for IoT systems

- Remote access through web-enabled control

Durability & Efficiency

- Designed for industrial environments

- Resistant to voltage fluctuations and physical wear

Form Factor

- Compact and modular design

- Easy integration into existing automation systems

Top Applications of the 4013HWBC Flip-Flop

1. Enhancing Cybersecurity and Secure Authentication

The 4013HWBC can act as a hardware layer in secure systems. It can manage authentication signals and ensure secure communication between devices.

2. Data Management and Storage

- Ensures reliable data storage in servers

- Supports automated data transfer for efficiency

- Reduces the risk of data loss

3. Powering Big Data and AI Solutions

- Integrates with machine learning pipelines

- Collects and sends real-time data for AI analysis

4. Integration with Blockchain and IoT

- Helps devices communicate securely in blockchain networks

- Supports smart home or industrial IoT setups

Why the 4013HWBC Stands Out from Similar Modules

The 4013HWBC differs from other flip-flops like BX-4013HWBC and CD4013BC in several ways:

- Web-enabled automation control for remote management

- Higher speed and reliability for industrial processes

- Modular integration with IoT, AI, and blockchain

Its flexibility and durability make it ideal for complex systems where other modules might fail.

Performance and Compatibility Comparison Table

| Feature | 4013HWBC | BX-4013HWBC | CD4013BC |

| Power Source | PoE / Wired | Wired | Wired |

| Connectivity | Ethernet / Wi-Fi | Ethernet | None |

| Applications | Automation, IoT, AI | General Logic | Educational |

| Manufacturer | ControlByWeb | Generic | Texas Instruments |

Benefits and Advantages

- Reliable connectivity for automation systems

- Supports remote monitoring and IoT integration

- Reduces system errors through high-speed switching

- Compatible with AI workflows and blockchain networks

Challenges and Limitations

- Requires technical knowledge for setup

- Limited wireless range without network infrastructure

- Firmware updates may be needed for advanced features

FAQs

Q1: What makes the 4013 HWBC different from traditional flip-flops?

It combines dual relay and input functionality with network connectivity, making it suitable for automation and IoT applications.

Q2: Is the 4013 HWBC compatible with existing industrial systems?

Yes, it integrates seamlessly with most industrial automation hardware and remote monitoring setups.

Q3: Can non-technical users set up?

Yes, setup is manageable with provided documentation and web-enabled configuration tools.

Q4: What industries use?

Common in manufacturing, data centers, cybersecurity systems, and IoT facilities.

Q5: How does the 4013HWBC support AI and machine learning?

Its high-speed processing ensures real-time data collection and integration with AI workflows.

Conclusion

The 4013HWBC is more than just a flip-flop module. Its combination of dual relay inputs, industrial-grade performance, and web-enabled connectivity makes it essential for modern automation and data systems. Whether you are managing IoT devices, integrating AI workflows, or securing data, this module offers reliability and efficiency.

Understanding its features, applications, and limitations will help you make better choices for your automation projects. By using the 4013HWBC, you can save time, reduce errors, and build systems that are future-ready.

Also Read: IDGod Review 2025: Inside the Technology, Risks, and Reality of the Fake ID Industry